Introduction:

In the industrial sector, heavy and complex load lifting operations are crucial for a wide range of industries, from construction and manufacturing to logistics. Lifting beams, designed to support these loads, are essential for the efficiency and safety of these operations. However, inadequate modeling or deficient analysis can have serious consequences, including structural failures, accidents, and material damage, resulting in economic losses and risks to personnel.

At BRAVNN, we understand the critical importance of precise load lifting structure modeling and are committed to providing solutions that prioritize safety, efficiency, and regulatory compliance. Our team of expert engineers applies the highest design and analysis standards, such as ASME BTH-1, to ensure the integrity and reliability of these essential devices.

Key Aspects for Optimal Load Lifting Structure Modeling:

To achieve load lifting structure modeling that meets safety, efficiency, and durability requirements, it is essential to consider the following aspects:

- Material Selection: Choose the appropriate materials to withstand loads, environmental conditions, and load cycles.

- Geometric and Load Analysis: Determine the optimal geometry and loads that the structure must support.

- Connection and Support Point Modeling: Design and simulate connections and support points to ensure correct load distribution.

- Stress and Deformation Analysis: Perform finite element analysis (FEA) to evaluate structural integrity under various load conditions.

- Testing and Validation: Implement a testing and validation program to verify model accuracy and structural integrity.

Material Selection:

Choosing the right material for a lifting structure is crucial to ensure its strength, durability, and compatibility with operating conditions. An unsuitable material can be susceptible to fatigue, deformation, or fracture, compromising structural integrity and endangering personnel and the environment.

Normally, A36 or S235 steel is the most common choice due to its excellent cost-benefit ratio, good weldability, and mechanical properties suitable for most applications. However, in certain circumstances, it is necessary to consider other materials:

| Material | Key Properties | Typical Applications | Observations |

| Low carbon Steel | Moderate strength, good weldability | General lifting applications | Favorable cost-benefit ratio |

| Stainless Steel | High corrosion resistance | Corrosive environments, food industry | Higher cost, excellent durability |

| Aluminum | Lightweight, good corrosion resistance | Light loads, mobile structures | Lower strength than steel |

| Alloy Steel | High strength, good toughness | Heavy loads, high fatigue applications | Requires special welding considerations |

Factors to consider in material selection:

- Mechanical Properties: Tensile strength, yield strength, fatigue strength, fracture toughness.

- Corrosion Resistance: Chemical compatibility, general and localized corrosion resistance.

- Operating Conditions: High and low temperature resistance, creep strength, oxidation resistance.

- Weldability: Ease of welding, welded joint strength.

Geometric and Load Analysis:

Geometric and load analysis is essential to determine the optimal structure configuration and loads it must support. This includes geometry analysis, load application points, and lifting conditions.

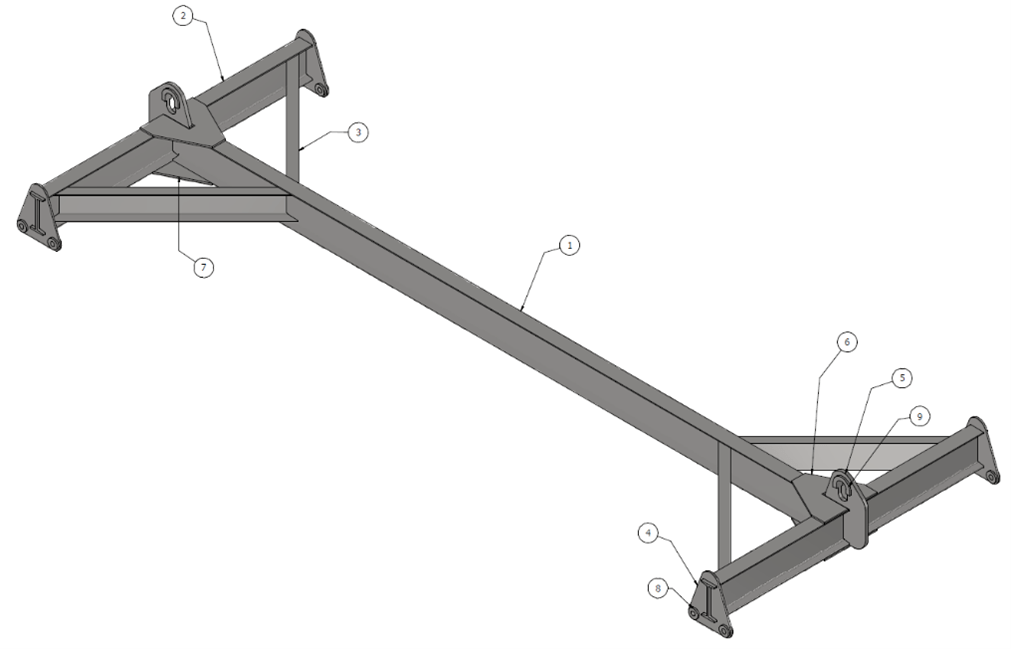

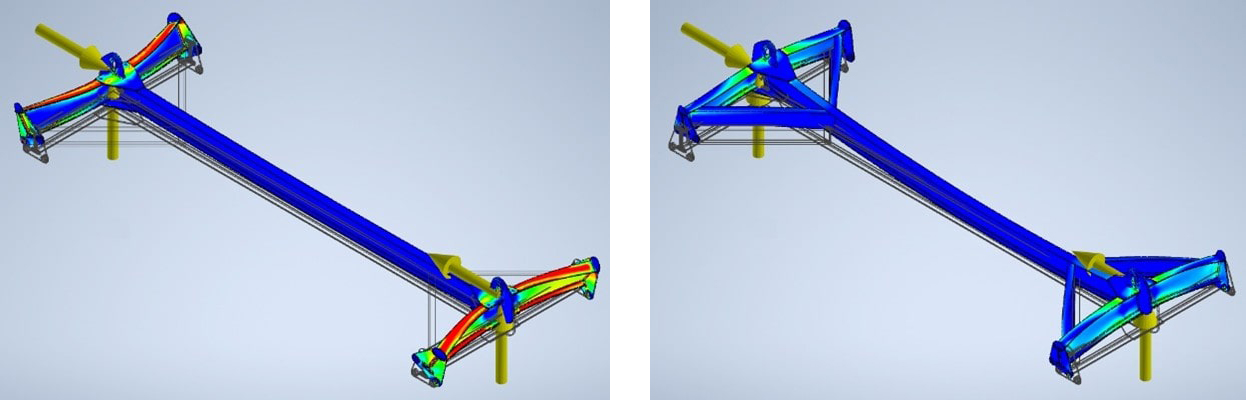

- Geometry: Study and design the structure to minimize unnecessary stress, bending, and/or torsion concentrations, attempting to channel forces as directly as possible from load points to lifting points. In the following images, you can see how the incorporation of stiffening elements significantly reduces stresses on the arms.

- Loads: Determination of static, dynamic, and load cycle loads the structure must support. The safety coefficient to be used primarily depends on this point.

- Lifting Conditions: Simulate lifting conditions to ensure correct load distribution and stability. The length of slings or chains to be used or the size of the crane hook are important factors when performing the analysis.

Connection and Fastening Point Modeling:

Precise modeling of connections and fastening points is essential to ensure realistic load distribution.

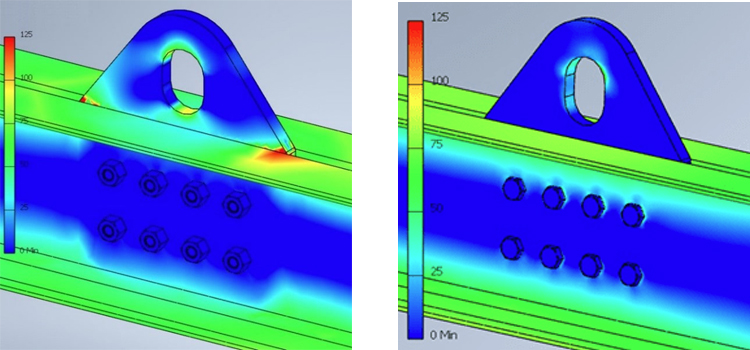

- Connections: Correct design and modeling of welded or bolted connections is crucial when evaluating stresses that may occur in contacts. All finite element programs incorporate a wide range of fixings or contacts, which rarely represent actual structural behavior. It is important to verify which type or combination of contacts and/or fixings we place in the model to recreate reality as closely as possible.

- Fastening Points: Simulating geometrically accurate fastening points is important to ensure the model behaves like the real one. As with connections, we must pay attention to the types of constraints we use to represent fastenings, whether loads or anchors. In the following images, you can see the same connection, under the same load state, but with different types of contacts between the parts:

Stress and Deformation Analysis:

Finite element analysis (FEA) allows evaluating stress and deformation distribution in the structure under various load conditions. This analysis helps identify weak points and optimize design.

- Static Analysis: Evaluation of stresses under constant loads.

- Dynamic Analysis: Evaluation of stresses under variable and dynamic loads.

- Fatigue Analysis: Evaluation of fatigue resistance under cyclic loads.

- Contact Analysis: Simulation of interactions between components.

When using finite element analysis, we must know that we incur the problem of singularities in the model. These are points where stress increases as the mesh is refined. Stress can greatly exceed material properties, but in reality, modeled parts do not fail. This phenomenon is mainly due to two factors:

- The first is that boundary conditions in the model are perfectly rigid, while in reality, they are not.

- The second is that in the model, we have sharp corners, since a zero-radius (0) fillet produces infinite stress, while in the real element, a small volume of material would exceed the elastic limit and the stress would quickly reduce to an admissible value.

This type of problem is not only observed in singularities but also, for example, in fastenings, where a sharp edge on a shackle can present stresses far above the yield point. In reality, these stresses would plastically deform the support point at the shackle’s sharp edge, distributing stresses and quickly reducing them to admissible values.

Testing and Validation:

Testing and validation are essential to verify model accuracy and structural integrity. This includes non-destructive testing (NDT) and load testing.

- Non-Destructive Testing (NDT): Radiography, ultrasound, magnetic particles, penetrant liquids are essential to verify that the final product matches the designed one.

- Load Testing: Static and dynamic tests must be performed to verify load capacity.

Benefits of Optimal Load Lifting Structure Modeling:

- Increased Safety: Minimizes the risk of failures and accidents.

- Increased Efficiency: Optimizes material use and reduces costs.

- Increased Durability: Increases structure lifespan.

- Regulatory Compliance: Ensures compliance with safety regulations and standards.

Conclusion:

Load lifting structure modeling is an arduous process requiring deep knowledge of materials, standards, and analysis techniques. At BRAVNN, we have the experience and tools to design structures that meet the highest safety and efficiency standards.

If you would like more information on how we can help you design or evaluate your lifting devices, please do not hesitate to contact us.